GES-AGM supplies all fine and medium grain size products. With our team of carbon and graphite experts, we can ensure the highest quality

products. Our plants and warehouses spanning from Brazil to the US give us the ability to fully serve the Americas.

Contact GES-AGM with your machined part challenges. We can help you succeed.

| Properties | Bulk Density | Particle Size | Electrical Resistivity | Flexural Strength | Compressive Strength | ||

|---|---|---|---|---|---|---|---|

| Grade | g/cc | inches / mm | Ω-inch 10-4 / µΩm | psi / MPa | psi / MPa | ||

| YBD | 1.55 | .031 / 0.8 | 16.7 / 41.8 | 2,350 / 16 | 6,600 / 46 | ||

| YBDX | 1.60 | .031 / 0.8 | 16.7 / 41.8 | 3,000 / 21 | 10,400 / 72 | ||

| YBDXX | 1.65 | .031 / 0.8 | 15.7 / 39.3 | 3,100 / 21 | 15,800 / 109 | ||

| CBY | 1.66 | .031 / 0.8 | 3.2 / 8.0 | 1,900 / 13 | 5,350 / 37 | ||

| AGSX | 1.72 | .031 / 0.8 | 3.1 / 8.0 | 2,200 / 15 | 6,500 / 45 | ||

| DBX | 1.74 | .031 / 0.8 | 3.0 / 7.5 | 2,300 / 16 | 6,600 / 46 | ||

| DBZ | 1.66 | .031 / 0.8 | 3.2 / 8.0 | 1,900 / 13 | 5,350/ 37 | ||

| CS | 1.74 | .031 / 0.8 | 3.0 / 7.5 | 2,300/ 16 | 6,600 / 46 | ||

| CS88 | 1.80 | .031 / 0.8 | 2.9 / 7.2 | 2,780/ 19 | 7,400 / 51 | ||

| CS114 | 1.75 | .031 / 0.8 | 3.0 / 7.5 | 2,300/ 16 | 6,600 / 46 | ||

| ECW | 1.74 | .031 / 0.8 | 3.0 / 7.5 | 2,300/ 16 | 6,600 / 46 | ||

| PF | 1.65 | 0.031 / 0.8 | 4.0 / 10.0 | 1,850 / 13 | 3,950 / 27 | ||

| PFR | 1.72 | 0.031 / 0.8 | 3.1 / 8.0 | 2,300 / 16 | 5,100 / 35 | ||

| PFR-N | 1.77 | 0.031 / 0.8 | 3.1 / 8.0 | 2,750 / 19 | 5,650 / 39 | ||

| PRD | 1.65 | 0.031 / 0.8 | 3.2 / 8.0 | 2,300 / 16 | 5,100 / 35 | ||

| PRD-N | 1.72 | 0.031 / 0.8 | 3.0 / 7.5 | 2,900 / 20 | 5,800 / 40 | ||

GES-AGM’s molded rounds offer diameters up to 72 inches. Our molded graphite products provide ideal options for a variety of applications including: heating elements and fixturing parts, for vacuum, pressure, and induction furnaces, centrifugal casting ring applications. Available in premium grades, our molded materials are offered in standard lengths up to 72 inches compressive strength of 5500 psi.

| Properties | Bulk Density | Particle Size | Electrical Resistivity | Flexural Strength | Compressive Strength | ||

|---|---|---|---|---|---|---|---|

| Grade | g/cc | inches / mm | Ω-inch / µΩm | psi / MPa | psi / MPa | ||

| PGW | 1.63 | 0.031 / 0.8 | 3.6 / 9.0 | 1,960 / 14 | 4,960 / 34 | ||

| PGR | 1.67 | 0.031 / 0.8 | 4.3 / 10.7 | 1,445 / 10 | 4,400 / 30 | ||

| PGX | 1.73 | 0.031 / 0.8 | 4.0 / 10 | 1,600 / 11 | 4,100 / 28 | ||

| 1.67 | 0.031 / 0.8 | 4.0 / 10 | 2,000 / 14 | 5,000 / 30 | |||

| PDF-N | 1.76 | 0.031 / 0.8 | 3.1 / 8.0 | 2,600 / 18 | 5,500 / 38 | ||

GES-AGM offers a set of four isostatically molded grades with a very fine grain size, increasing strength and density, and excellent machinability. Our isostatically molded graphite products offer a range of grades with densities from 1.65 to 1.93 g/cc. This graphite is commonly used in sintering trays, crucibles, electronic encapsulating fixturing, EDM, continuous casting dies, and heating elements. With exceptionally fine grain structure our iso-molded graphite stands out with superior close tolerance machinability, density and overall strength.

| Properties | Bulk Density | Particle Size | Electrical Resistivity | Flexural Strength | Compressive Strength | ||

|---|---|---|---|---|---|---|---|

| Grade | g/cc | inches / mm | Ω-inch / µΩm | psi / MPa | psi / MPa | ||

| XTJ10 | 1.76 | 0.0002 / 5 | 5.1 / 13.0 | 7,250 / 50 | 13,050 / 90 | ||

| XTJ15 | 1.77 | 0.0005 / 12 | 4.1 / 10.5 | 6,380 / 44 | 12,325 / 85 | ||

| XTC10 | 1.83 | 0.0002 / 5 | 5.1 / 13.0 | 8,700 / 60 | 14,500 / 100 | ||

| XTC15 | 1.82 | 0.0005 / 12 | 4.1 / 10.5 | 7,250 / 50 | 12,325 / 85 | ||

| PFI-15 | 1.78 | 0.0006 / 15 | 4.6 / 11.7 | 5,800 / 40 | 11,000 / 74 | ||

| PFI-25 | 1.80 | 0.0005 / 12 | 5.0 / 12.5 | 7,850 / 54 | 14,800 / 102 | ||

| PFI-35 | 1.86 | 0.0004 / 10 | 6.8 / 17.0 | 9,300 / 64 | 17,500 / 121 | ||

| PFI-45 | 1.93 | 0.0002 / 5 | 6.0 / 15.0 | 10,750 / 74 | 20,000 / 138 | ||

GES-AGM offers a complete family of graphite grades. The very fine 5 micron grain size allows for fine detail machining of thin cross sections and very smooth finished surfaces. These grades are recognized worldwide and offer guaranteed, consistent, highly efficient EDM performance. We offer a full line of EDM graphite that is globally recognized for exceptional quality and efficiency. An ideal choice for general finishing applications as well as close detail finishing and roughing, each of these products is guaranteed to have the highest consistency and performance available. For fine detail machining, including smooth finished surfaces and thin cross-sections, consider our very fine 5 micron grain size.

| Properties | Bulk Density | Particle Size | Electrical Resistivity | Flexural Strength | Compressive Strength | ||

|---|---|---|---|---|---|---|---|

| Grade | g/cc | inches / mm | Ω-inch / µΩm | psi / MPa | psi / MPa | ||

| PFE-3 | 1.80 | 0.0004 / 10 | 4.3 / 11 | 7,600 / 53 | 13,500 / 93 | ||

| PFE-6 | 1.85 | 0.0002 / 5 | 6.3 / 16 | 8,700 / 60 | 16,500 / 114 | ||

| PFE-9 | 1.91 | 0.0002 / 5 | 5.3 / 13 | 10,700 / 74 | 20,000 / 138 | ||

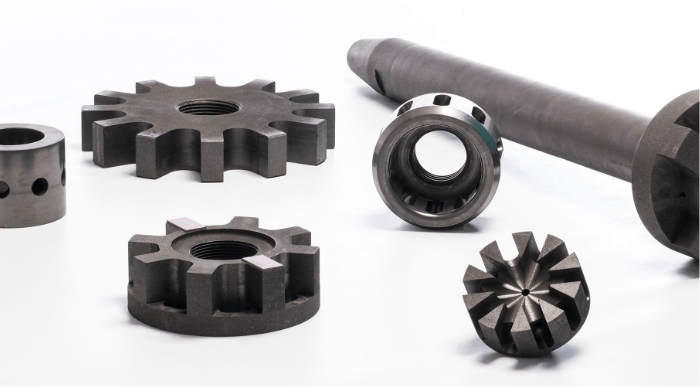

At GES-AGM, we offer ultra-durable and high-performance grades with impregnation options with antimony and resin materials. Our materials are used to produce mechanical parts for applications that require low friction and low wear. Each of the products is guaranteed to superior physical stability, self-lubrication, corrosion resistance and oxidation resistance. These mechanical carbon products are excellent in the manufacturing of low-friction, low-wear machine parts. All of our materials have a guarantee that they will perform just as well or better than what you are currently using.

| Properties | Impregnation | Bulk Density | Hardness | Compressive Strength | Max Temp | ||

|---|---|---|---|---|---|---|---|

| Grade | g/cc | Shore | psi / MPa | °C | |||

| C170K | Resin | 1.72 | 95 | 29,877 / 206 | 350 | ||

| C180K | Resin | 1.82 | 80 | 29,007 / 200 | 300 | ||

| C230D | Antimony | 2.30 | 78 | 28,282 / 195 | 350 | ||

| G177 | None | 1.77 | 85 | 5,656 / 39 | 450 | ||

| G180 | None | 1.80 | 70 | 11,603 / 80 | 482 | ||

Oxidation can be an issue on some graphite products during manufacturing processes. To mitigate this damage, GES-AGM offers a proprietary LoOx™ treatment to ensure extended durability and performance on many of our products. This solution is offered in our U.S. and Brazilian facilities, and more information about this effective treatment is available through our sales team.